RECOMMENDED PRODUCTS

ABOUT US

Conglin Aluminum- Tech(Dalian)Co., Ltd.

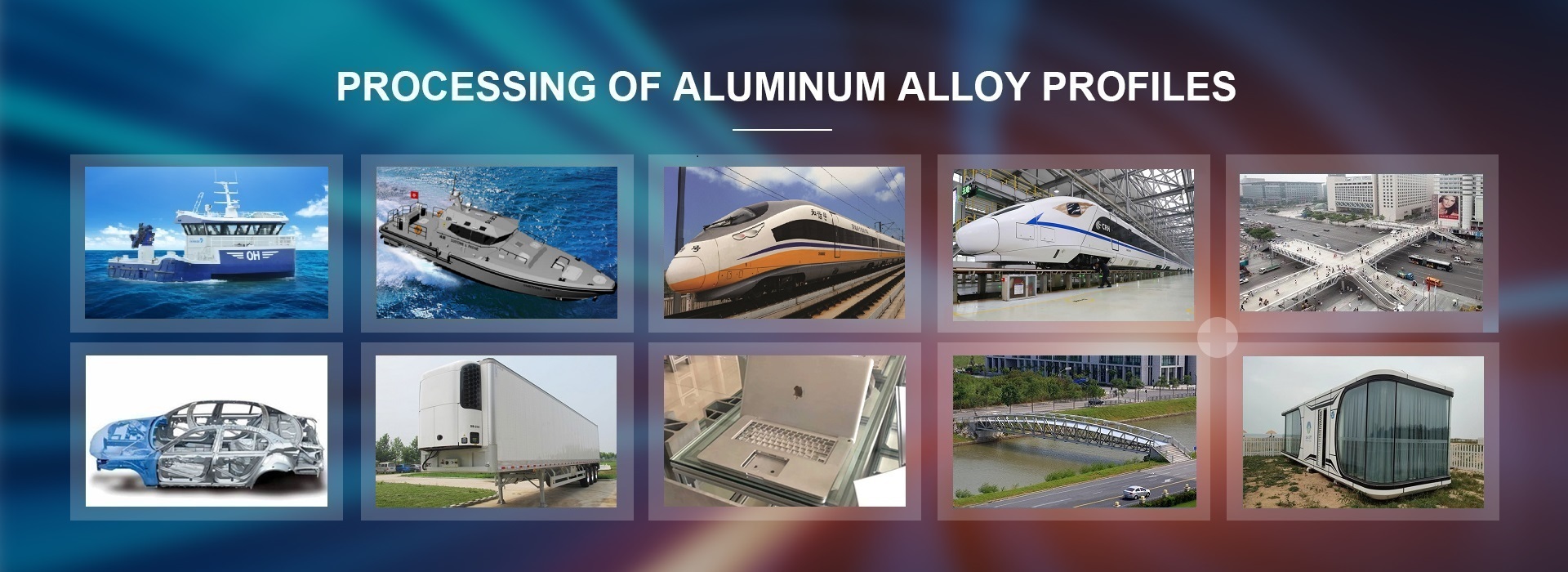

Conglin Aluminum-Tech (Dalian) Co., Ltd established in 1992, we have evolved into China's leading enterprise specializing in R&D and precision manufacturing of high-performance aluminum alloys and advanced lightweight solutions.

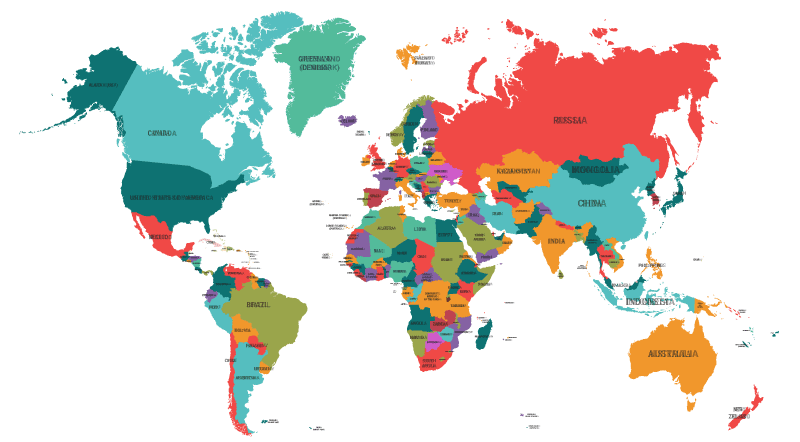

With three decades of technological innovation, we operate eight specialized divisions encompassing diverse sectors including aluminum alloy profiles, high-speed rail car bodies, architectural formwork systems, construction materials, industrial extrusions, container truck components, automotive parts, and marine applications. Our vertically integrated production system employs a workforce exceeding 1,600 professionals dedicated to delivering engineered aluminum solutions across global industries.

Contact Info: Eric@aluminum-pm.com

View More +

Conglin Aluminum- Tech(Dalian)Co., Ltd.

Conglin aluminum processing industry started in 1992 and has developed into the most professional research and development and manufacturing enterprise of high-end industrial aluminum profiles and aluminum alloy lightweight equipment in China.

After 30 years of development, the company has 8 branches mainly engaged in aluminum alloy profiles, high-speed rail bodies, building templates, building materials, industrial profiles, container trucks, automotive parts, ships, etc There are more than 1600 employees.

Contact Info: Eric@aluminum-pm.com

View More +

SUCCESS CASE

NEWS

15

2025

-

07

How to Choose a Safe Motor Enclosure for a Specific Environment

As a company specializing in the development and production of safe motor housings, this article describes how to select safe motor housings for specific environments based on practical experience. For different scenarios such as dusty, humid, flammable and explosive, high temperature, etc., from the protection level, material properties, structural design and other dimensions, analyze the core requirements of safe motor enclosure in terms of dust-proof, water-proof, explosion-proof, heat dissipation and operational safety, etc., and emphasize the key role of safe motor enclosure on the stable operation of the equipment and avoidance of potential safety hazards.

14

2025

-

07

How to improve the welding quality and productivity of aluminum welding locomotives?

In the manufacturing industry, the welding quality and production efficiency of aluminum welding locomotives are directly related to product quality and corporate benefits. In this paper, from the technology upgrading, process optimization, material selection, equipment maintenance and personnel training in five dimensions, to explore the key measures to improve the performance of aluminum welding locomotives, including the introduction of laser welding, digital double-wire welding and other advanced technologies, precise adjustment of welding parameters, the use of high-quality welding materials, regular maintenance equipment, and strengthen the skills of the operators, through a comprehensive approach to achieve the quality of aluminum welding locomotives welded with the efficiency of the double enhancement. Double enhancement of aluminum welding locomotive welding quality and production efficiency is achieved through comprehensive measures.

11

2025

-

07

Lightweight Aluminum Trucks Customize How Highly Recyclable They Are

As a company focusing on the customization of lightweight aluminum trucks, our company always takes the high recycling rate as its core competitiveness. In terms of design, aluminum alloy accounts for more than 85% of the core components of lightweight aluminum trucks, and the high proportion of single material design reduces the difficulty of recycling and dismantling; through the construction of a “closed-loop processing system” with top enterprises, intelligent dismantling has made the recycling rate of aluminum alloy components of lightweight aluminum trucks reach 92%, and the performance loss of recycled aluminum materials is only 3-5%, which can be directly used for re-production. It can be directly used for re-production. Our customized services further optimize the details of recycling, such as modular design, “trade-in” services, etc., so that the recycling rate of the whole life cycle of lightweight aluminum trucks is stable at over 95%. This not only fulfills our environmental responsibility, but also brings real economic value - the recycling revenue from retired lightweight aluminum trucks can cover 15%-20% of the initial purchase cost. In the future, we will continue to promote material innovation, so that lightweight aluminum trucks will continue to have value in the cycle.

CONTACT US